Morning Star looks to new packaging options as wood prices continue to rise

One of the many benefits of purchasing tomato products from Morning Star is the ability to choose how your product comes. We offer 3 main types of packaging: wood bins, plastic bins, and 55-gallon drums. The most common option that our customers choose is the wood bin. Wood bins have many benefits, which include multi-year reusability, fill capacity, efficiency in standard plywood sheet sizing, ease of manufacturing, recyclability, waste-to-energy power generation, and the often overlooked ability to turn the wood bin into a clean plastic bin by removing the Bin-Top and draping the interior blue Poly Bin-liner down the outside sidewalls of the filled wood box. Some higher-level benefits are overall strength due to the outward pressure (hoop strength) seen in the aseptic bag fill process, ability to store them long-term outdoors in adverse weather conditions due to compressive stacking, and ability to withstand the harsh railroad boxcar transportation environment over a potential 3,000-mile journey. These are all great benefits, but the most popular reason why people choose to use wood bins is because of the low cost.

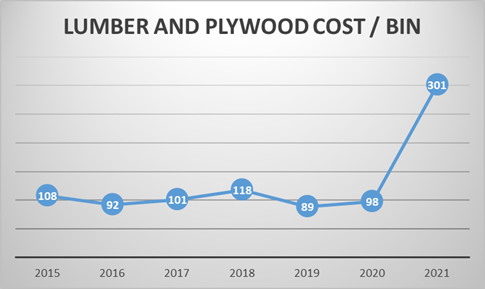

Due to many complications over the last 12-18 months, the cost to produce wooden bins has gone up astronomically. There have been record-setting price increases due to shelter at home orders, reduced factory staffing mandates, unexpected weather, reduced imports, increased demand for new homes and home improvement projects, and many others.

WOOD BIN

Historically, these specific products have been price-stable with minor increases and decreases over time. Since late 2020 to current, 2021, there has approximately been a 200-250% price increase in the wood bin and other plywood and lumber-based packaging components. (See chart 1). This increase is shown by the sharp price increases in standard GMA (Grocery Manufacturers Association: 40” x 48”) shipping pallets, which are used for safe and efficient unitized Bag-in-Drum shipments.

The demand for plywood panels continues to drive the western plywood prices higher with several mills spending time off the market for preventive maintenance or lack of complete staffing. This, combined with a lack of some import products that typically enter the US market from international origins has minimized supply. In listening to wood suppliers and experts in the market, we are hopeful that prices will start to soften in the 1st or 2nd quarter of 2022.

As a way to offer value to our customer base by minimizing expected short-term higher prices in plywood, Morning Star is offering limited units of an innovative IBC (Intermediate Bulk Container) produced by Goodpack USA, Inc. This new IBC is called the Goodpack MB6 TomatoCube. It is made of 100% galvanized steel and was introduced to the California bulk tomato processors in 2019-2020. The MB6 may be a new secondary package concept, but the Goodpack company of products has been in existence since the late 1990’s with sizes that were not usable for Morning Star or our customers.

The Goodpack logistics approach is different. Goodpack will deliver a clean, usable unit to the Morning Star factory in a ready-to-use condition. Morning Star will fill (sealed aseptic bag) and store the unit until the customer requests shipment. Once the product is used by the customer, the 4-sided hinged sidewalls will fold down and collapse onto the metal base and the separate metal cover is then placed onto the knocked down bin to create a completely knocked down 2-piece assembly. The customer will then contact Goodpack directly for immediate pickup, thus relieving the return shipping cost back to California.

Morning Star prides itself on partnering with innovators to ensure that new products are good for our customers. In the case of the MB6, units were tested to ensure bin assembly, powered and roller conveyance, high-pressure filling, long-term outdoors storage, and pre-shipping high-pressure water cleaning were all acceptable for our customers. Morning Star was privileged to be involved with the Association of American Railroads’ testing that was completed for the 50-Foot standard boxcar at the Transportation Technology Center, Inc.’s full-scale testing facility in Pueblo, CO in 2018. Morning Star is committed to continuing this involvement and support for future boxcar railroad testing in 2021.

MB6 Railcar Testing

We are also always looking for ways to minimize high wood bin costs by expediting the return of in-transit wood bins from customers and efficiently utilizing other unused IBC styles that might become available prior to this upcoming pack season.

2020 and the early part of 2021 have proved to be challenging times for many packaging supplies and components, but the commitment for innovation, validation and supplier-customer partner-shipping relationships will always be the mission for creating value for our customers and their needs.

###

Morning Star Newsletter now distributed electronically

As a reminder, Morning Star is now distributing our newsletters electronically using an email distribution vendor called Mailchimp. Your e-version will now include informative Morning Star videos and highlights. Depending on your company's firewall, these emails may initially be directed to you spam folder.