A reliable supply of consistent quality.

Many factors influence a customer’s reliable supply of product and their ability to receive a consistent quality year after year. By focusing on key factors that influence the short-term and long-term supply, Morning Star ensures the highest reliability of meeting product quantity and quality expectations.

Maximizing supply reliability through factory locations, tomato sourcing alignment, and a large diversified grower base.

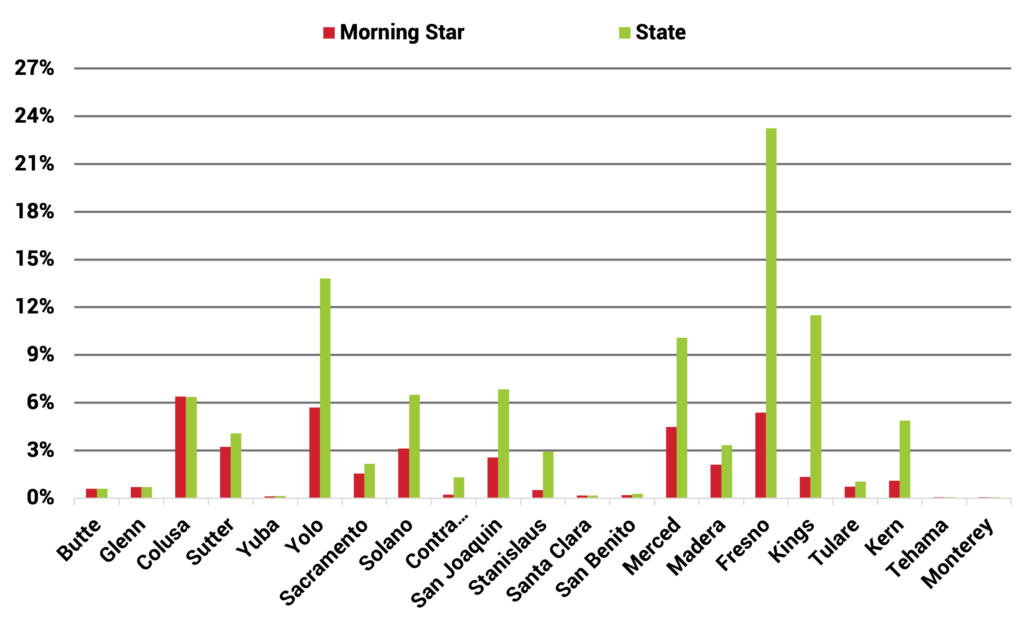

Our factories’ geographically unique locations allow us to minimize the risks of crop failure and inclement weather by sourcing a proportionately equal volume of our tomatoes from each of the counties that grow tomatoes in California. On an annual basis, we carefully select and contract with over 150 California family owned and operated growers to ensure the quality and quantity of our tomatoes. Our grower selection is based on performance, field, and crop conditions.

California is the most prolific tomato growing region in the world for a reason. Known for its predictably long, hot and rain free summers, this fertile valley consistently produces 10 to 12 million tons (approx. 9.1 – 10.9 million mT) of processed tomatoes every season. Making up 96% of the domestic supply and 33% of the global tomato ingredient market.

- Less disease pressure due to the Central Valley’s hot and dry climate.

- Harvesting Season

- California: 90-100 days

- Global average: 45 days

Our vertical integration has a purpose.

We prioritize leadership, innovation and scale, as well as integrated coordination efficiencies. We grow approximately half of our transplants and transplant them in the fields. We also harvest and truck virtually all of our tomatoes.

We harvest and haul our tomatoes from the field to the factory in the lightest weight trailers available. These allow us to bring in the freshest tomatoes around the clock in fewer loads, then process and pack them within 4 hours of harvesting.

Why Morning Star?

Simplifying the process to improve efficiency and sustain a global industry.

Built for large scale efficient production, our factories’ streamline designs leverage gravity and size. This enables us to maintain reliable production throughout the season, including a dedicated organic line at our Liberty Packing Co. (Santa Nella) facility.

As shown in the graph, our facilities have only increased and sustained plant capacities over the past 30 years.

Morning Star Factory Capacities

With a proven track record and a solid reputation for honesty and integrity, fostered by Morning Star’s founder Chris Rufer, the organizational culture of Morning Star maintains the integrity of our Guiding Principles.